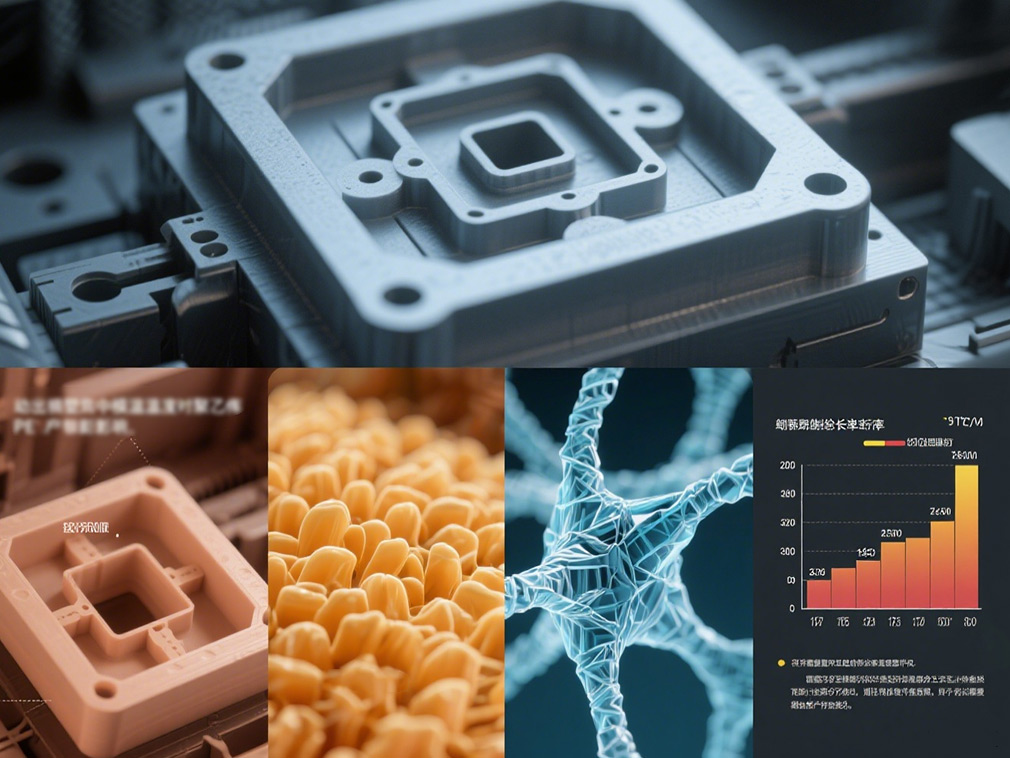

Factors Shaping PE Elongation

Polyethylene (PE) is a widely used plastic material. Its elongation at break is affected by a variety of factors. By deeply analyzing these factors, we can better understand and regulate the performance of PE materials.

Molecular structure: the foundation of performance

The molecular structure of PE plays a decisive role in its elongation at break. The molecular chains of linear low-density polyethylene (LLDPE) and high-density polyethylene (HDPE) are linear structures, with less entanglement between molecular chains and regular arrangement. When subjected to tensile force, the molecular chains can slide and stretch relatively easily, making the material have a higher elongation at break.

Taking LLDPE as an example, its unique short branched chain structure increases the interaction between molecular chains. During the stretching process, the branched chain can serve as a node for stress transmission, allowing the molecular chains to be gradually pulled apart, thereby giving the material good ductility. Cross-linked polyethylene (XLPE) forms chemical bonds between molecular chains through chemical or physical methods. This body mesh structure restricts the movement of molecular chains.

When a tensile force is applied to XLPE, the molecular chain is difficult to slide freely, and the material quickly reaches the tensile limit and breaks, so its elongation at break is much lower than that of PE materials with a linear structure.

Processing technology: the key to shaping performance

The processing technology has a significant impact on the elongation at break of PE. In the extrusion molding process, temperature control is particularly important. If the extrusion temperature is too high, the thermal motion of the PE molecular chain will intensify, the intermolecular force will weaken, and the material fluidity will increase, but it will lead to a decrease in the orientation of the molecular chain.

After cooling, the internal structure of the material will be loose, and local weak points will easily appear during stretching, which will reduce the elongation at break. On the contrary, if the temperature is too low, the material will not be plasticized well, the molecular chain cannot be fully stretched, and the internal stress will be concentrated, which will also reduce the elongation at break.

During injection molding, the mold temperature and cooling rate will affect the crystallinity and molecular orientation of PE products. Lower mold temperature and faster cooling speed will cause PE to crystallize quickly and form a large number of fine crystals. These crystals restrict the movement of molecular chains, resulting in a decrease in elongation at break. Properly increasing the mold temperature and slow cooling are conducive to the formation of larger crystals and good molecular orientation, which can improve the elongation at break of the material to a certain extent.

Additives: a boost to performance optimization

The use of additives is also an important factor affecting the elongation at break of PE. The addition of fillers such as calcium carbonate and talcum powder will destroy the continuity and regularity of PE molecular chains. The interaction between filler particles and PE molecular chains is weak.

During the stretching process, stress concentration is easily generated around the filler particles, becoming the origin of cracks, thereby reducing the elongation at break of the material. For example, when the calcium carbonate filling amount reaches 30%, the elongation at break of PE material may drop by more than 50%.

Plasticizers can significantly improve the flexibility and elongation at break of PE. Taking dioctyl phthalate (DOP) as an example, the plasticizer molecules are inserted between the PE molecular chains, weakening the forces between the molecular chains and making the molecular chains easier to slide.

After adding an appropriate amount of DOP, the elongation at break of the PE material can be increased by 30% - 50%, and the material becomes softer and less prone to breakage.

In addition, although the main function of additives such as antioxidants and light stabilizers is not to improve the elongation at break, they can effectively inhibit the aging and degradation of PE during processing and use, and indirectly maintain the tensile properties and elongation at break of the material.

Our platform connects hundreds of verified Chinese chemical suppliers with buyers worldwide, promoting transparent transactions, better business opportunities, and high-value partnerships. Whether you are looking for bulk commodities, specialty chemicals, or customized procurement services, TDD-Global is trustworthy to be your fist choice.